Development of hybrid welding at TRL4 (WP3)

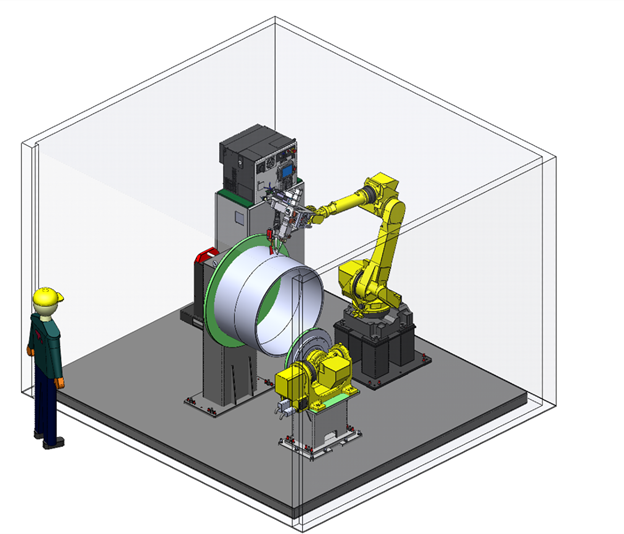

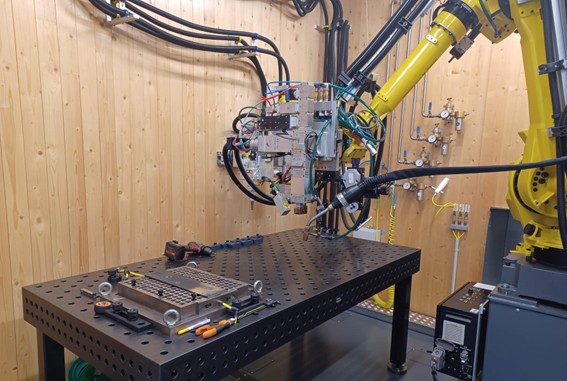

Definition, design, and implementation of facilities for laser hybrid welding at Optoprim.

- Impression of welding cell

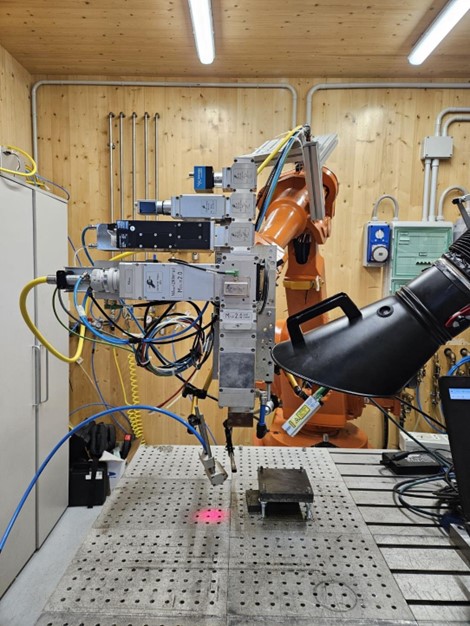

- Implementation of laser welding equipment

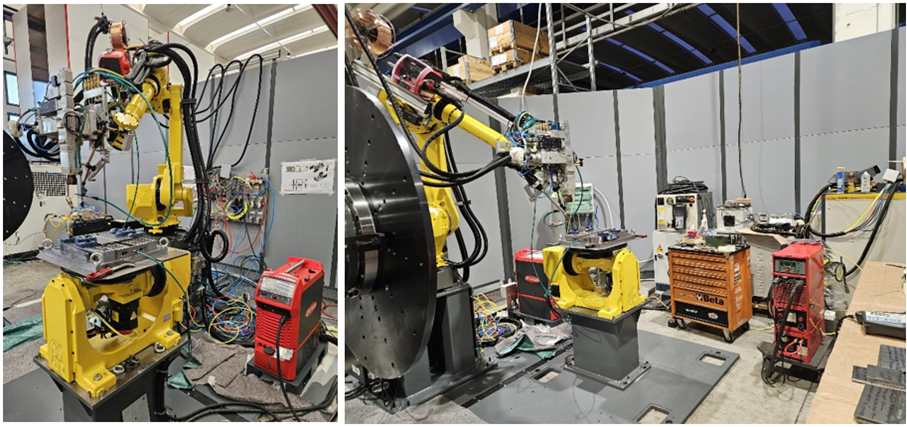

- Hybrid laser-MAG welding setup

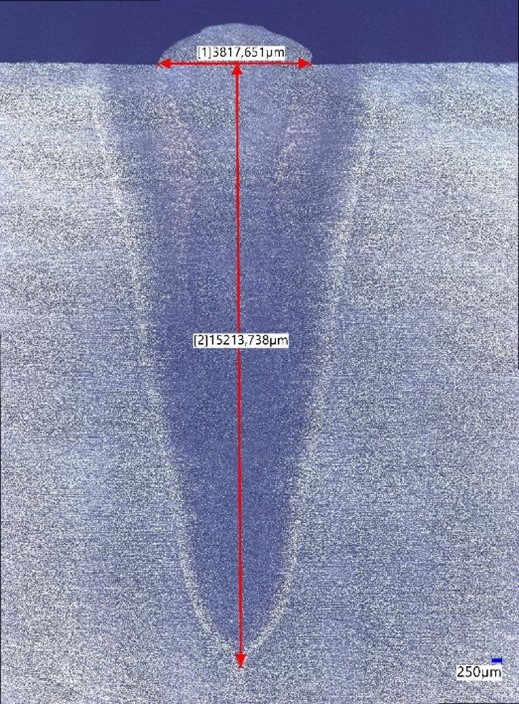

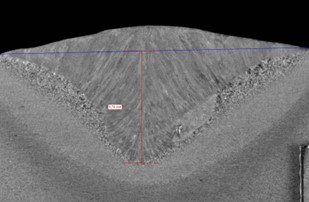

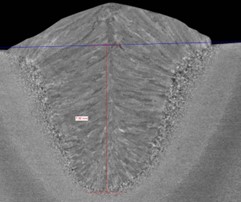

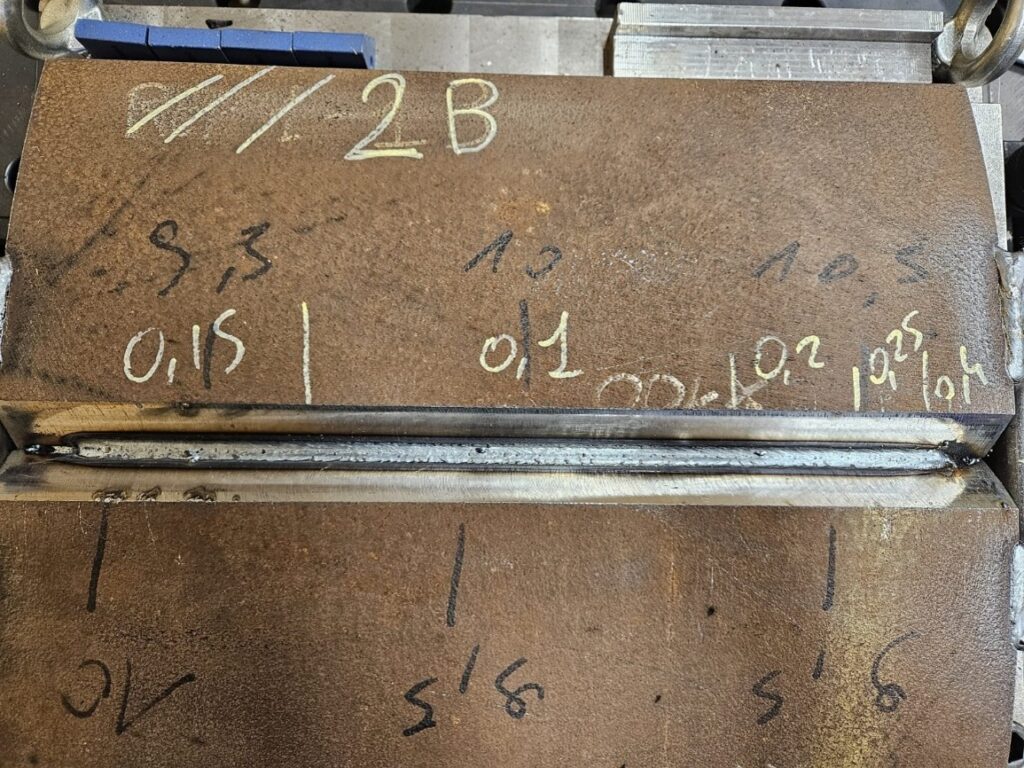

- Laser welding trials using S355 steel grade at Optoprim: effect of laser power, focal plane, fiber diameter, and welding speed on weld penetration

- Example: 6kW, 100µm fibre, 0.5m/min

- Laboratory station for plasma + MAG hybrid welding

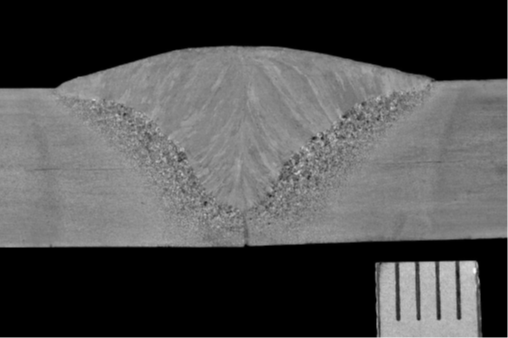

- Preliminary bead-on-plate trials with plasma + MAG welding; an increased electrical current in MAG results in an increased depth of penetration

- Butt joint made by plasma + MAG welding; 8mm thick S700MC steel plate

WP3 – Welding activities at Optoprim (September 2025)

As part of the SMARTWELD project (RFCS-2022, GA No. 101112414), welding activities within Work Package 3 are progressing at Optoprim, with technical support from CSM.

On 18 September 2025, several welded joints were produced using high-strength steels X80 and X100, selected for their industrial relevance and mechanical performance.

During this session, key process parameters – laser power and welding speed – were varied to evaluate their influence on weld quality. The resulting samples will undergo detailed characterization as foreseen in Task 3.3, providing essential input for validating the hybrid welding and monitoring strategies developed within the project.

These activities contribute to advancing the SMARTWELD system toward higher Technology Readiness Levels and demonstrate the strong collaboration between project partners.

Development of online monitoring at TRL4 (WP4)

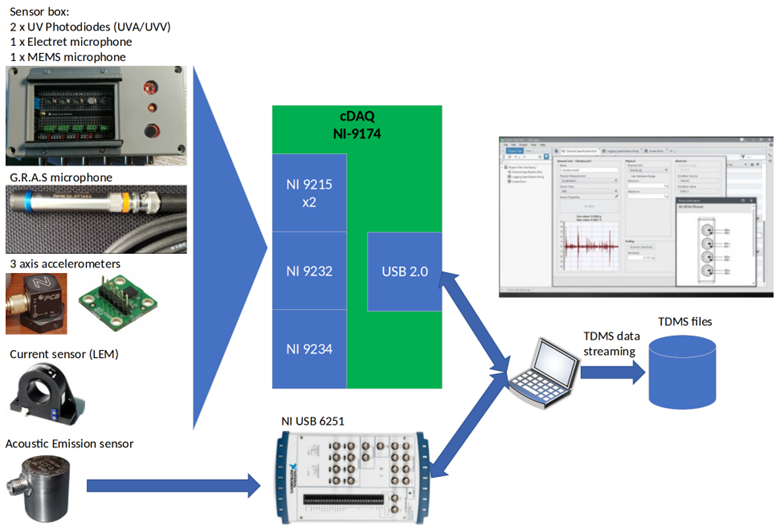

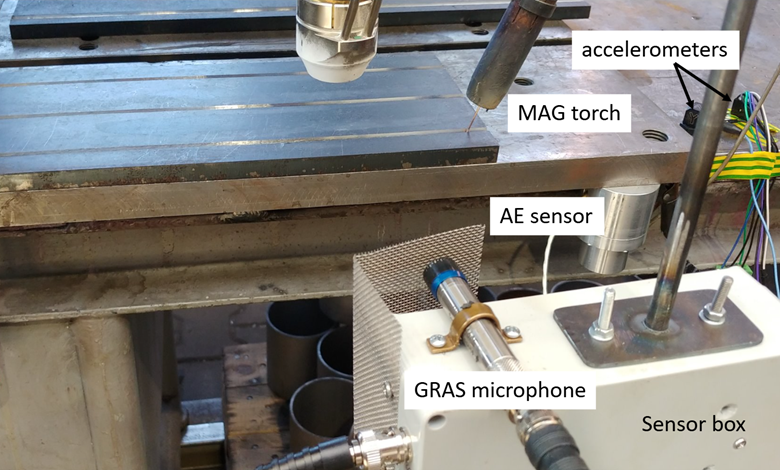

Definition and implementation of an online quality monitoring system at Silesian University of Technology

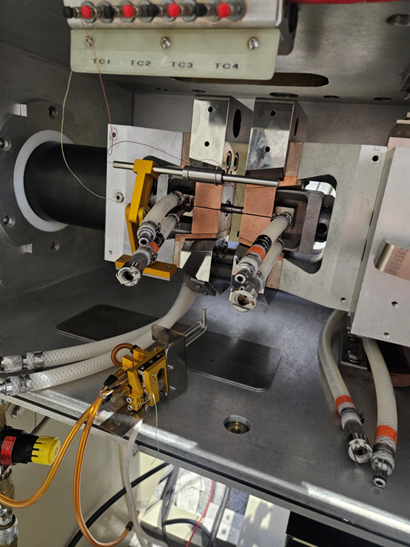

- Overview of data acquisition system

- Laboratory set-up

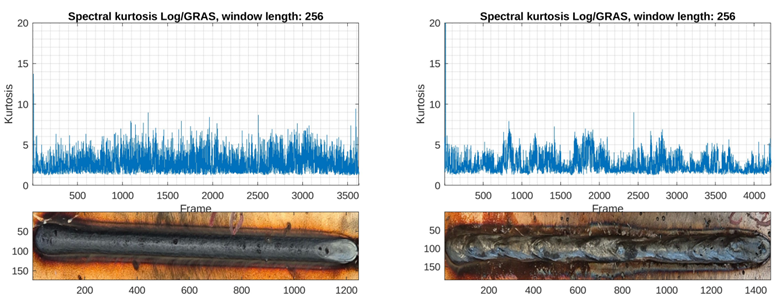

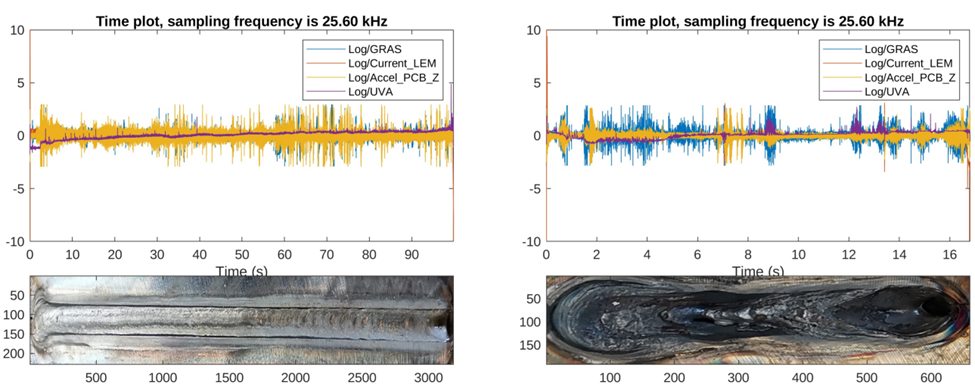

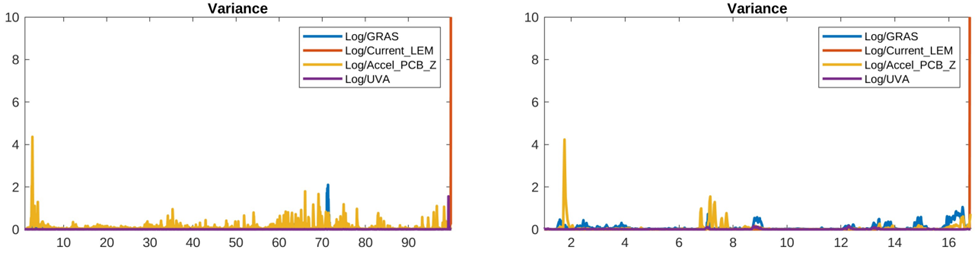

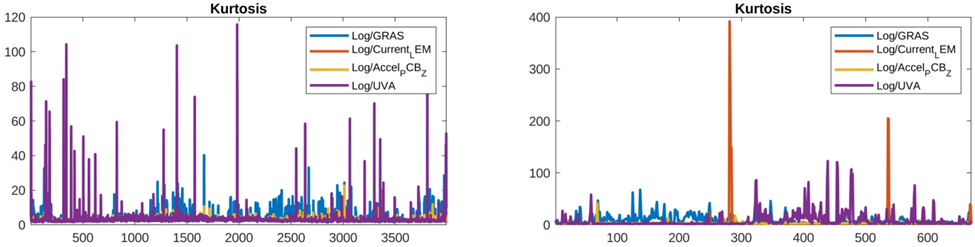

- Feature extraction during bead-on-plate MAG welding experiments

- Results from plasma arc welding on plates of 8mm and 10mm thickness

WP4 – SUT–OPT collaboration on monitoring system development (October 2025)

As part of the Smartweld project (RFCS), partners SUT and Optoprim carried out a joint working session in Vimercate, Italy, focusing on data acquisition and the development of the online monitoring system.

Laser Beam Welding trials on S355 steel were performed with intentionally introduced defects to assess the capability of the monitoring system to detect and predict welding imperfections.

The collected weld data and NDT results will now support the refinement and validation of the real-time monitoring tool.

This collaboration marks an important step in the development of Smartweld’s intelligent quality monitoring system.

Development of predictive tool at TRL4 (WP5)

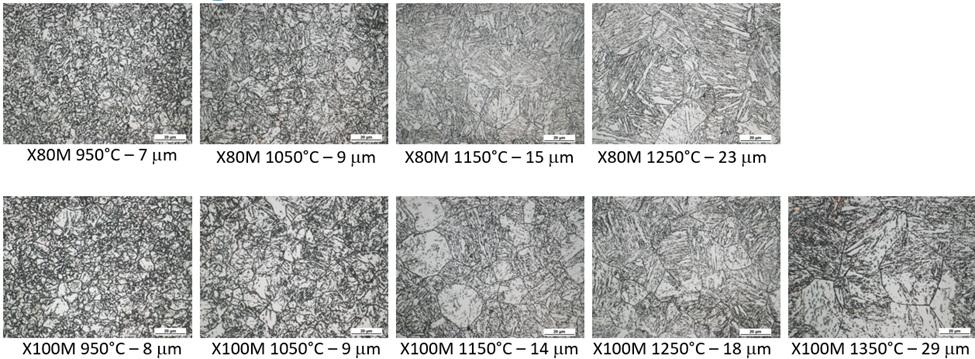

Preliminary activities to support the predictive tool: characterization of material properties

- Physical simulation using Gleeble 3500 to determine prior austenite grain size (PAGS), continuous cooling transformation (CCT) diagram

- High temperature tensile testing